Protect your ONE-KEY™ compatible tool by locking it out whenever it’s not in use. Any ONE-KEY™ app will automatically keep records of the last time it was within 100ft of your ONE-KEY™ compatible tools, allowing you to pinpoint missing items quickly.

Keep a virtual eye on your things when you can’t. Pull reports on recent spend, run inventory audits, even see the cradle-to-grave story of any item in your inventory. Manage your equipment down to the project level. Snap receipts, log purchase info, set up service reminders, and assign tools out to your employees. Keep the important information right at your fingertips. Get started today to streamline your productivity. Combining a free-to-use inventory program with the industry’s smartest tools, ONE-KEY™ provides a new level of control and access to information that will revolutionize the way work gets done. You can flag the tool as lost or stolen," Lambert said.Introducing ONE-KEY™, the first digital platform for tools and equipment. If a tool was to grow legs and walk off the job, we recognize it’s outside the geo fence and can send a message to the owner. So once I transfer tools to that job site, those tools know where they live. "Another thing we can do with that tracking network is we can put a geo fence around that job site. The tracking system can also let operators know if tracked tools have left a certain job site. It doesn't have to be a Milwaukee tool," Lambert said. "It might be a ladder, or a truck or a toolcase. Tools that don't come with ONE-KEY standard can be equipped with the TICK Tool and Equipment Tracker that adheres to larger equipment, or durable Asset ID tags that can be used with any kind of equipment from any manufacturer. Lambert said Milwaukee has been averaging about 5-6 million location updates per day throughout the US.

#Milwaukee tools one key Bluetooth#

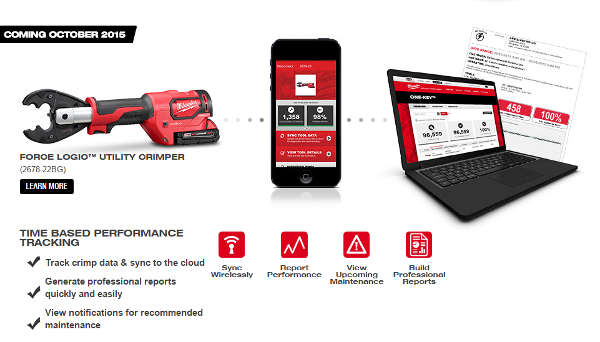

With ONE-KEY, tools are connected via Bluetooth signal to a network that keeps track of their position, as well as data on how often the tool has been used, how many times it has been charged, and how it's being used. "You could disable, for example, a table saw after everyone goes home from the job site so that if anyone comes up and messes with it, the tool won’t work without me enabling it," Lambert said. The connected tool experience can also increase workplace safety. I could turn on, for example, the self-tapping screw feature, and make sure the tool operator isn’t going too fast or too hard."

I could limit RPM values, torque values, trigger ramp-up speed. "ONE-KEY can also customize the controls of the tools itself. I can enable the non-binding feature to eliminate kickback and potentially save someone an injury," Lambert said. "Say I have a drill that is starting to bind up. The app, which runs on mobile devices and the web, was first introduced about 5 years ago, but has matured since then.Īndrew Lambert, Milwaukee’s Group Program Manager for ONE-KEY told Utility Products that the company has over 50 tools integrated with ONE-KEY smart tool technology, but ONE-KEY’s asset management platform can be used to manage an entire inventory, regardless of manufacturer. Milwaukee Tool is adding new capabilities to its connected tool and equipment management application, ONE-KEY.

0 kommentar(er)

0 kommentar(er)